The Future of Automated Welding

FBR's Mantis™ is a game-changing robotic welding system designed for defence and heavy fabrication sectors, including mining, shipbuilding, and large-scale industrial manufacturing. It directly addresses critical industry challenges such as skilled labor shortages, productivity bottlenecks, and the need for adaptable automation

Its core stability and precision are enabled by FBR's world-leading Dynamic Stabilisation Technology™ (DST®).

Key Features

Unlock New Levels of Productivity & Precision

Unmatched Stability & Precision: With FBR's Dynamic Stabilisation Technology™ (DST®) at its core, Mantis™ delivers consistent, high-quality welds by actively compensating for environmental factors and robot arm dynamics.

Boost Productivity: Minimize downtime with faster installation and continuous operation thanks to the pendulum workspace design. Expect up to 4x the productivity of a manual welder.

High Deposition Welding: Achieve deposition rates of up to 25kg/hr, matching sub-arc speeds with the flexibility of a robotic arm, reducing setup time and part manipulation.

Seamless Integration & Workforce Advantage

Automate Complex Welds: Effortlessly handle thick plate with fully automated multi-pass welding, ensuring superior quality and consistency on demanding jobs.

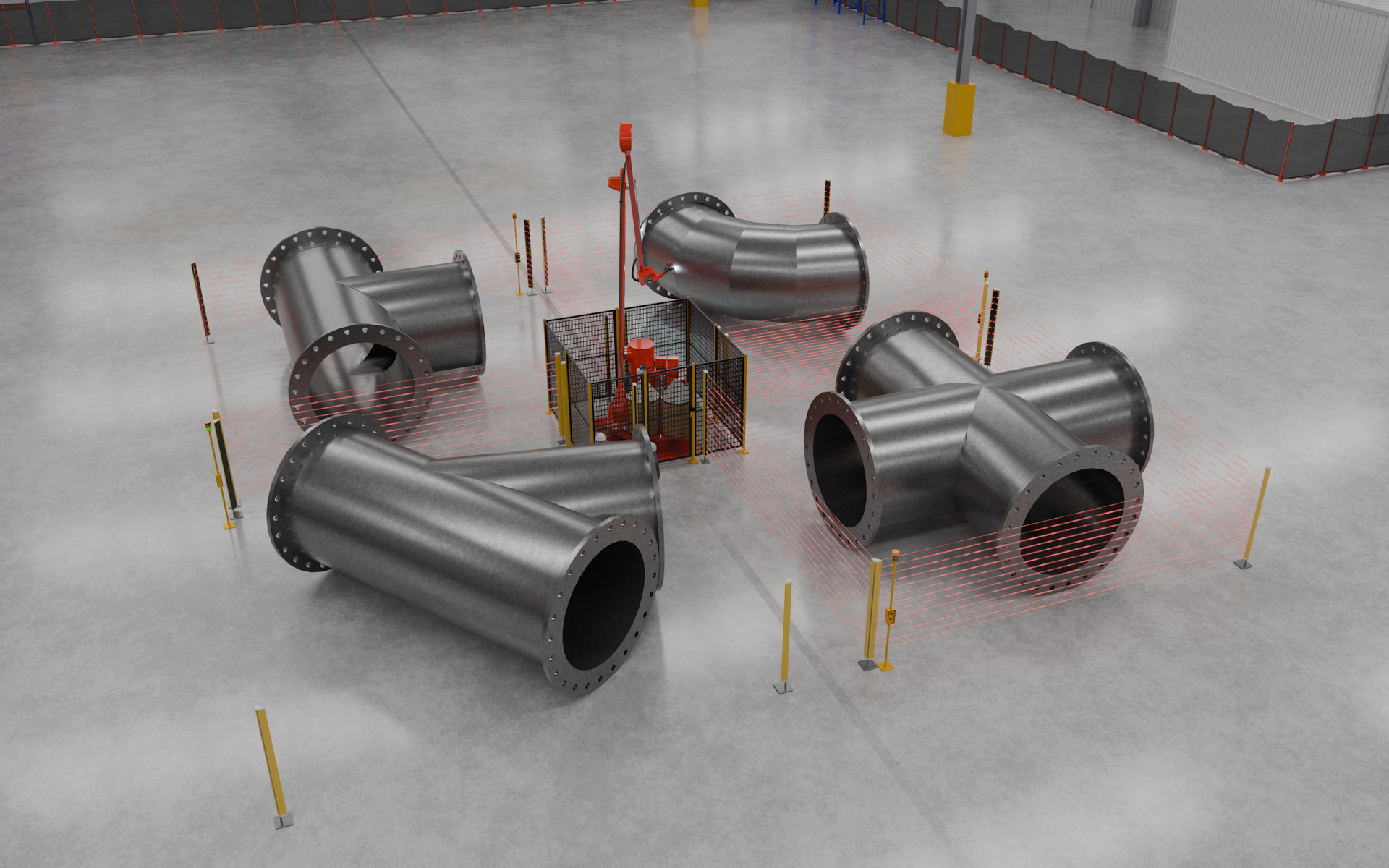

Optimize Your Space: Free up valuable factory floor with a nimble robot that doesn't need bulky infrastructure.

Highly Adaptable: Integrate your preferred welding equipment and programming packages for a seamless fit into your existing operations.

Address Labor Challenges: Enhance your workforce capabilities and address skills shortages with reliable, high-quality automated welding.

| Robot Name: | FBR Mantis™ |

|---|---|

| Core Technology: | FBR Dynamic Stabilisation Technology™ (DST®) |

| Reach: | 8 m |

| Mounting: | Fixed base (no gantry or linear axis required) |

| Footprint: | 3 x 3 m |

| Welder Options: | Standard (Single Wire): Fronius TPS400i High Deposition (Tandem Wire): 2 x Fronius TPS 500i |

| Weld Deposition: | Up to 25 kg/hr (with tandem wire setup, subject to part specific limitations) |

| Tandem Welding: | Yes |

| Programming: | Verbotics, onboard controls for simple tasks, adaptable to other software packages |

| Seam Tracking: | Laser Scanner system |

| Welding Speed: | Up to 4,000 mm/min |

| Travel Speed: | 10 m/min |

| Safety: | Designed to be integrated with AS 4024 compliant safety work cell |

| Workspace Configuration: | Supports pendulum operation between 2 or 4 workspaces |

| Working Area – Single Bay: | 12 x 5 x 5 m |

| Working Area – Dual Multi Bay: | 9 x 4 x 5 m |

| Working Area – Quad Multi Bay: | 6.5 x 4 x 5 m |

| Joint Ranges: | J1 (Slew): ±185° J2 (Shoulder): 0° - 155° J3 (Elbow): 0° - 175° |

| Welding Wire Capacity: | 2 x 250 kg drums |

| Lifetime: | 40,000 hrs |

| Ingress Protection: | IP53 |

| Operating Temperature: | 0-45°C |

Apply to be an early adopter

Be among the first to learn more about the FBR Mantis™ robotic welder, with deliveries starting Q1 2026 calendar year.

This isn't just a robotic welder – it's your path to a 4x productivity boost over manual welding. Achieve payback in under two years in high-utilisation settings, driven by substantial savings in manual welding costs and increased throughput.

Ready to see what Mantis™ can do for your bottom line? Contact us to discuss why your company should have early access to Mantis™.

We have noticed that your browser doesn't have Javascript enabled. Our form system requires it to be enabled. Please click here for instructions on how to enable Javascript.